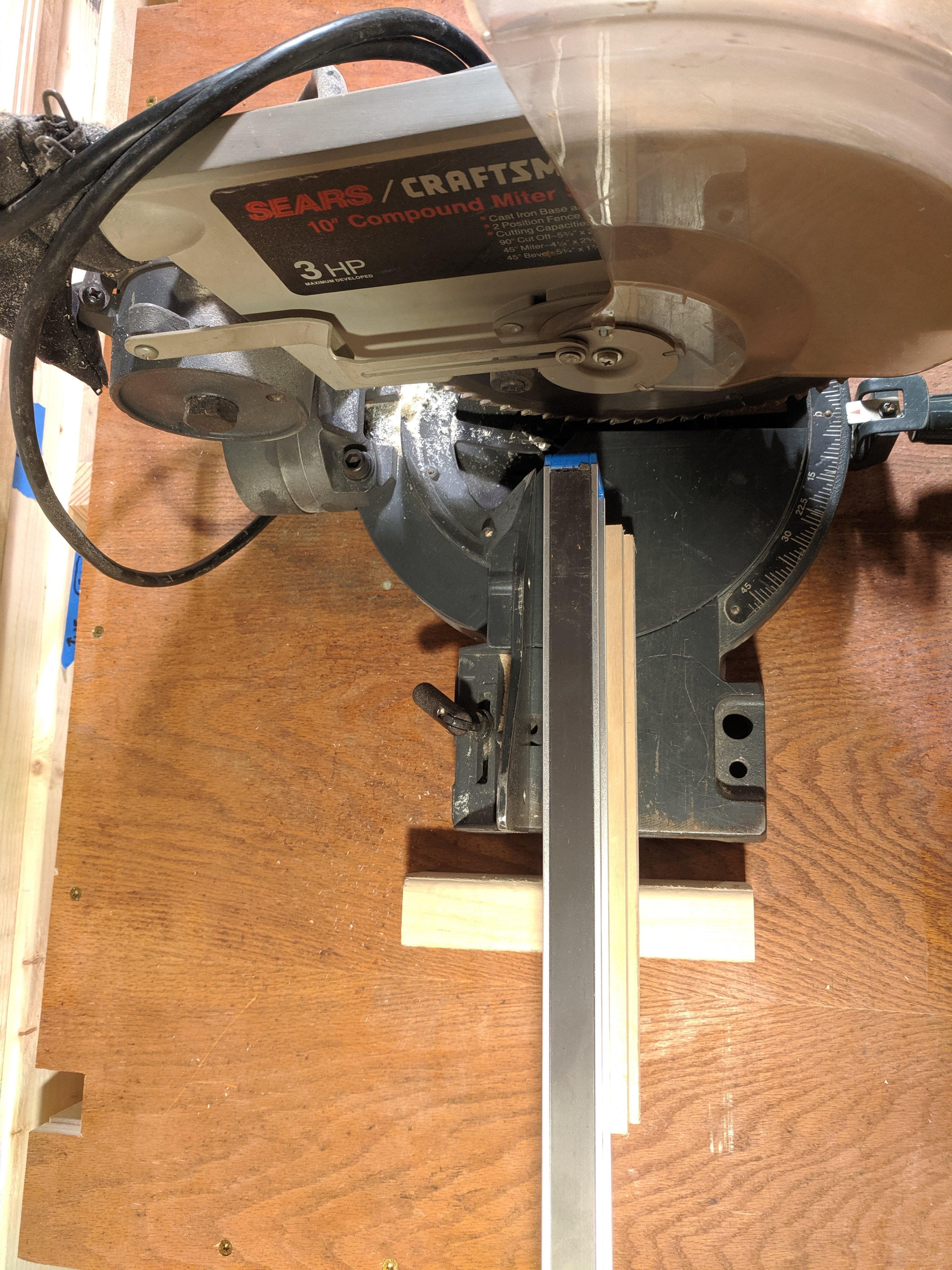

I’ve built the section of the table that flips. On the saw side, I have 1-1/2" to build up so the bed of the saw is flush with the rest of the table. How would you attach the saw so it’s secure to flip upside down?

The top only has holes at the front, for inserting a side clamp.

Maybe bolt through the ends into a block underneath?

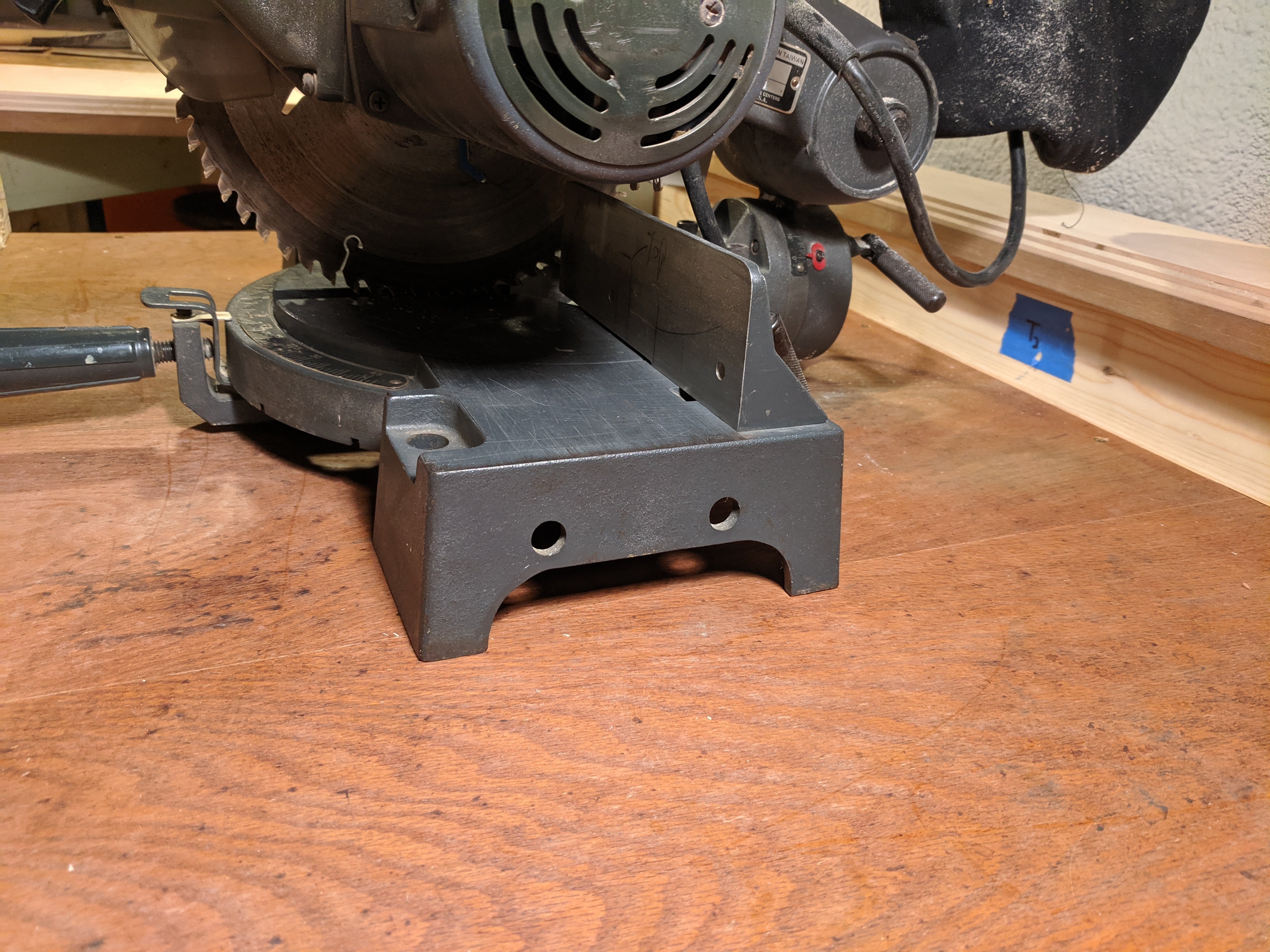

U bolts worked out very well!

Glad to hear it. In revisiting it, the steel will be harder than the casting, which is also a bit thin below those holes, but if it doesn’t wiggle a ton, and you don’t just drop the whole contraption on the ground, it should last quite a while.

Good caution. It doesn’t seem to shift and I tend to flip it pretty slowly, so hopefully it won’t put undue stress on the casting.